The Current Landscape of Printed Medicine Packaging Boxes

The global market for printed medicine packaging boxes is experiencing significant growth. According to recent industry reports, the market is projected to expand at a substantial compound annual growth rate (CAGR) in the coming years. This growth is driven by several factors, including the booming pharmaceutical industry worldwide. The continuous development of new drugs and the increasing prevalence of chronic diseases in many countries have led to a higher demand for pharmaceutical products, subsequently fueling the need for high-quality packaging.

For instance, in emerging economies like India and China, the pharmaceutical sectors are witnessing rapid expansion. As more people gain access to healthcare, the production and consumption of medicines are on the rise. This growth directly translates into a greater requirement for printed medicine packaging boxes to safeguard and present these pharmaceutical products effectively.

Market Trends Shaping the Industry

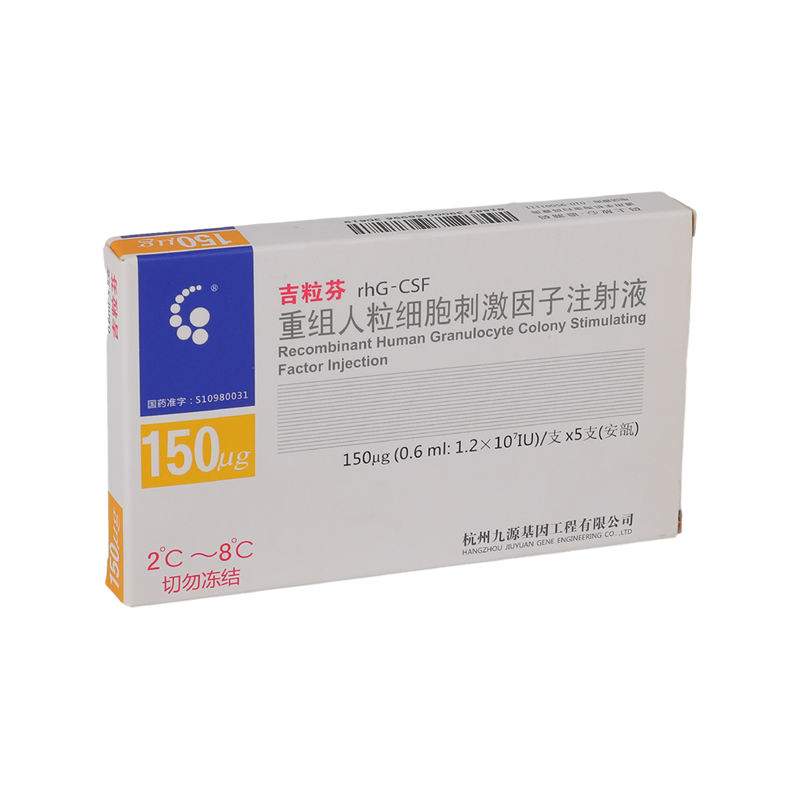

Stringent Regulatory Requirements

One of the key trends in the printed medicine packaging boxes industry is the compliance with strict regulatory standards. Governments around the world are imposing more rigid regulations regarding pharmaceutical packaging to ensure patient safety. These regulations cover aspects such as the use of tamper-evident features, clear labeling of ingredients and dosage instructions, and the prevention of counterfeiting.

Manufacturers of printed medicine packaging boxes must invest in advanced technologies and materials to meet these regulatory demands. For example, the use of special inks that are resistant to fading and tampering, as well as the incorporation of holographic elements or unique barcodes for product authentication, has become increasingly common.

Rising Demand for Sustainable Packaging

With the growing global awareness of environmental issues, there is a significant shift towards sustainable packaging solutions in the pharmaceutical industry. Consumers are now more conscious about the environmental impact of products they use, including medicine packaging. As a result, there is a rising demand for printed medicine packaging boxes made from eco-friendly materials such as recycled paperboard, biodegradable plastics, and plant-based fibers.

Pharmaceutical companies are recognizing the importance of sustainability and are actively seeking packaging suppliers that can offer green options. This trend not only benefits the environment but also enhances the brand image of pharmaceutical companies, making them more appealing to environmentally conscious consumers.

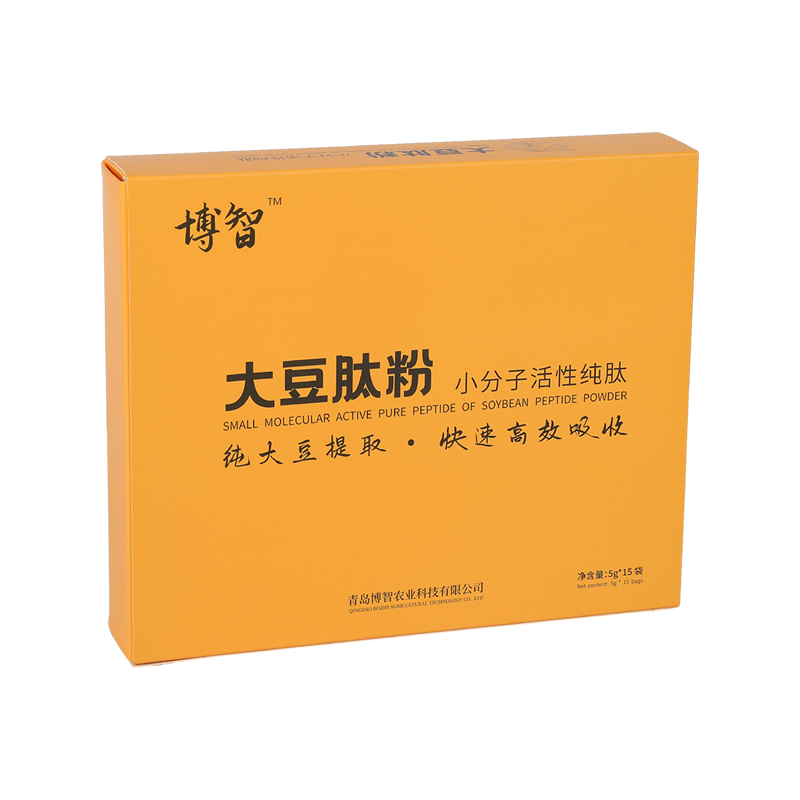

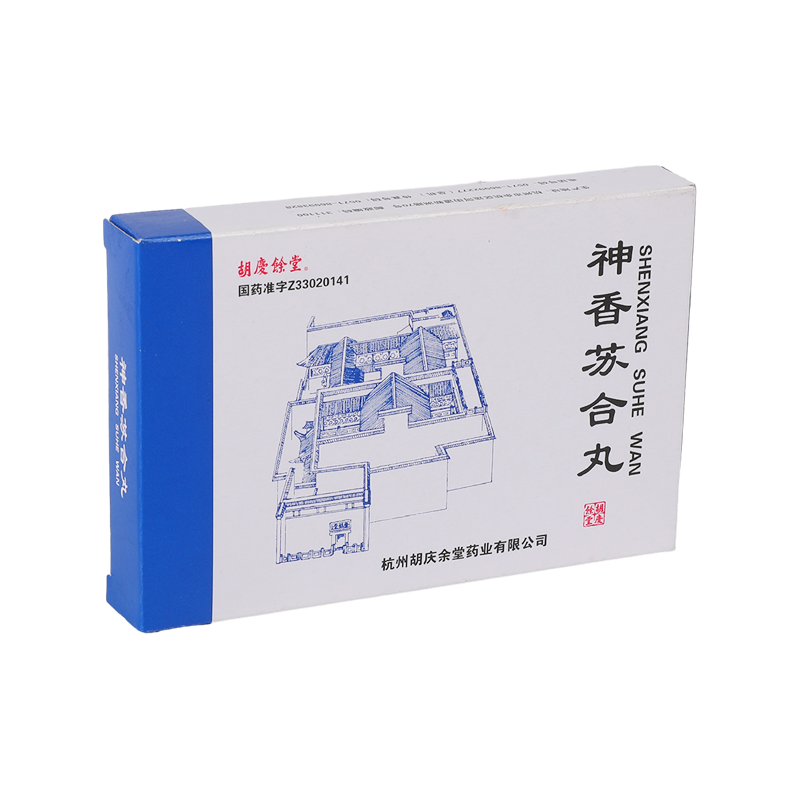

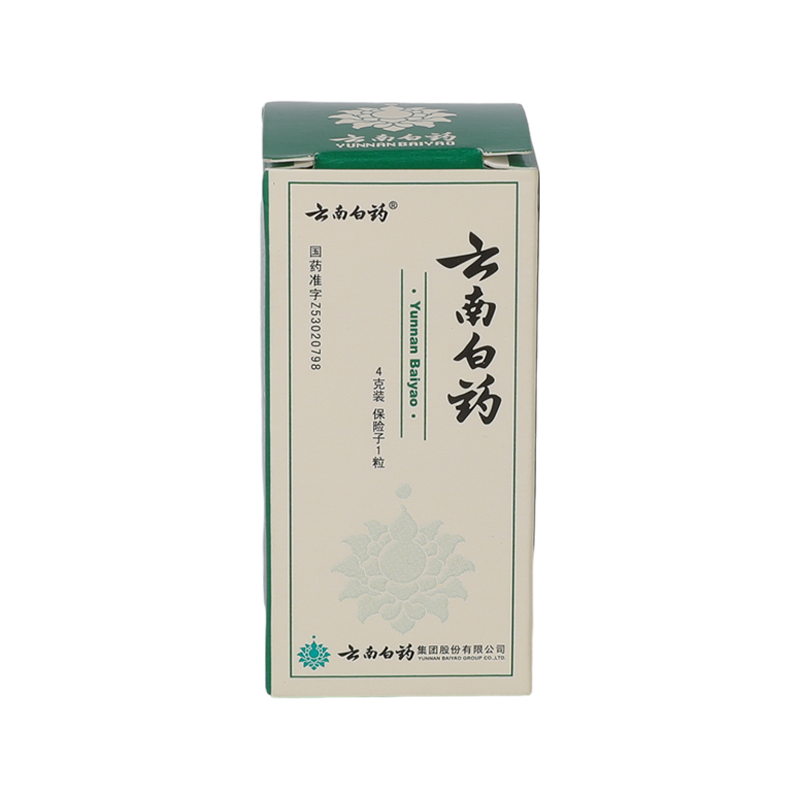

Customization for Brand Differentiation

In a highly competitive pharmaceutical market, brand differentiation is crucial. Printed medicine packaging boxes play a vital role in helping pharmaceutical companies stand out from the crowd. Customization of packaging has become a key trend, allowing companies to create unique designs that reflect their brand values and identity.

Pharmaceutical companies are now collaborating closely with packaging designers to develop eye-catching and informative packaging. This includes using vibrant colors, engaging graphics, and easy-to-read typography. Customized printed medicine packaging boxes not only attract consumers but also make it easier for patients to identify and use their medications correctly.

Innovation in Printed Medicine Packaging Boxes

Smart Packaging Technologies

The integration of smart technologies into printed medicine packaging boxes is an exciting development. Smart packaging can include features such as temperature sensors, humidity indicators, and time - temperature indicators. These sensors can provide real - time information about the storage conditions of the medicine, ensuring its quality and efficacy.

For example, a temperature - sensitive label on a printed medicine packaging box can change color if the medicine has been exposed to temperatures outside the recommended range. This alerts healthcare providers and patients that the medicine may no longer be safe or effective to use. Such smart packaging technologies are especially important for medications that are sensitive to environmental conditions.

Advanced Printing Techniques

Advancements in printing techniques have also revolutionized the printed medicine packaging boxes industry. High - resolution digital printing allows for the creation of intricate and detailed designs on packaging boxes. This enables pharmaceutical companies to print complex graphics, small text for important information, and even variable data such as batch numbers and expiration dates with great precision.

Another emerging printing technique is the use of 3D printing for packaging prototypes. 3D printing allows for the rapid creation of customized packaging designs, which can be tested and refined before mass production. This not only speeds up the product development process but also reduces costs associated with traditional prototyping methods.

In conclusion, the printed medicine packaging boxes industry is on a growth trajectory, driven by various market trends and technological innovations. As the pharmaceutical industry continues to expand globally, the demand for high - quality, sustainable, and customized printed medicine packaging boxes will only increase. Manufacturers and pharmaceutical companies alike need to stay abreast of these developments to thrive in this competitive market.

English

English 中文简体

中文简体 русский

русский عربى

عربى