Functional design of medical cartons

Medical Paper Boxes are both sturdy and lightweight in functional design. Its multi-layer structure provides superior compressive resistance and can effectively avoid damage caused by stacking or collision during transportation. At the same time, this design can also meet the strict requirements of the pharmaceutical industry for products to be moisture-proof, dust-proof and pollution-proof, thereby ensuring the safety and effectiveness of medical products.

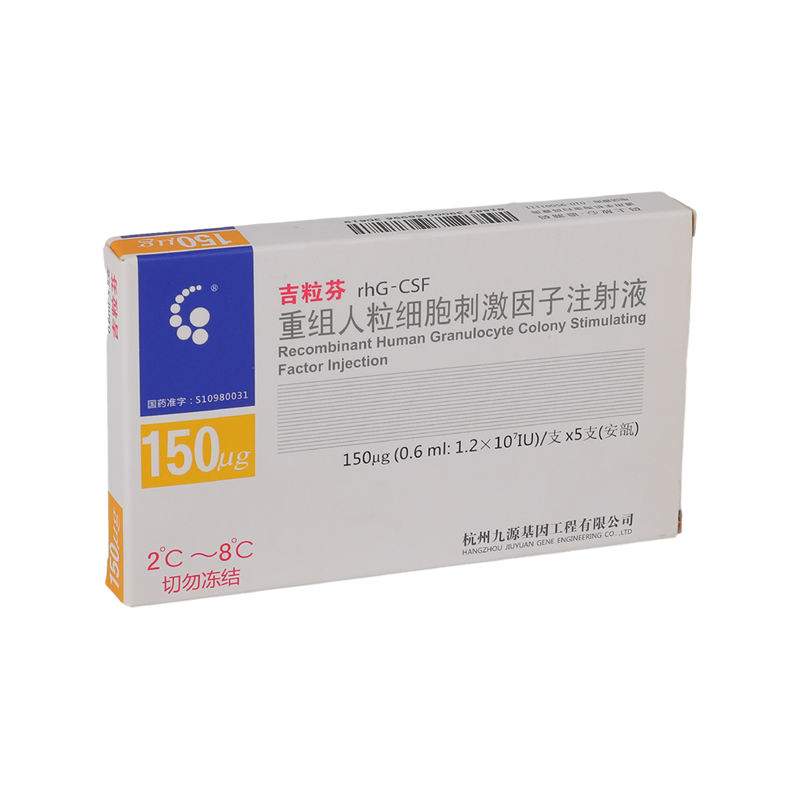

Additionally, high-performance medical cartons perform well in internal partition and cushioning design. For example, by customizing the lining, additional protection can be provided for fragile products such as syringes, reagent bottles, etc. For temperature-controlled products, these cartons can also combine thermal insulation materials and refrigerants to provide a more stable environment for the product.

Performance in transportation

Vibrations and bumps during transportation pose serious challenges to the integrity of medical products. Medical Paper Boxes utilizes optimized material and structural design to ensure stability under harsh transport conditions. For example, its compressive and tear resistance properties can protect the product inside the packaging from external impacts. In addition, medical cartons have significant advantages in weight, which reduces transportation costs while also improving transportation efficiency.

To meet different transportation needs, high-performance medical cartons can also be combined with smart tags or QR code technology. This not only improves traceability in the logistics process, but also facilitates the rapid identification of product information in the transportation chain, further improving transportation efficiency.

Advantages in storage

Medical products usually have strict requirements on storage conditions, such as humidity, temperature and light. The multi-functional protective layer design of Medical Paper Boxes effectively prevents the environment from affecting the product. For example, some high-performance medical cartons are made of special coatings that prevent moisture penetration and are suitable for humid or variable storage environments.

In addition, the flexibility of these cartons in size and shape also helps healthcare organizations make more efficient use of storage space. The modular design allows the carton to be stacked neatly during storage, reducing the footprint and making it easy to access quickly.

Sustainability and environmental protection advantages

While ensuring high performance, Medical Paper Boxes also fully reflect the concept of sustainable development. With recycled paper as the main raw material, these cartons reduce the burden on the environment and can be completely recycled and reused. Compared with traditional plastic packaging, the carbon footprint of medical cartons emit significantly lower during production and use, providing an environmentally friendly packaging solution for the medical industry.

Future trends of industry development

In the future, Medical Paper Boxes will usher in more development opportunities in terms of intelligence and customization. For example, smart cartons combined with IoT technology will be able to monitor environmental parameters for drug transportation and storage in real time. At the same time, with the application of 3D printing technology, the design of medical cartons will be more flexible to meet more complex medical product packaging needs.

English

English 中文简体

中文简体 русский

русский عربى

عربى